- Before beginning the replacement process, ensure you have the right tools at hand. These typically include a screwdriver, pliers, a new set of wheels compatible with your door model, and a level to ensure the door is balanced correctly. It's essential to choose the right type of wheels; consult your door's manual or contact the manufacturer for guidance if necessary.

- Iron casting as a craft dates back to ancient times, but it was during the Industrial Revolution that it truly flourished. The process involves melting iron, pouring it into molds, and allowing it to cool and solidify into the desired shape. The result is a piece that is not only strong and resilient but also visually captivating, thanks to the intricate details that can be achieved through casting.

stainless steel door roller. Whether it's a sliding glass door, a barn door, or a heavy industrial door, there is a stainless steel roller that can meet the specific requirements of the application. This adaptability makes stainless steel door rollers a popular choice among architects, builders, and property owners looking for a reliable and versatile door hardware solution.

On the other hand, wrought iron fencing is celebrated for its timeless aesthetic and artisanal qualities. The hand-forged nature of wrought iron permits a wide range of output: everything from simple designs to highly intricate workmanship that can be more detailed than most cast iron. The forging process also imparts wrought iron fences with a higher resistance to impact and bending, making them more durable in certain environments.

The definition of “wrought” in Merriam-Webster Dictionary is “worked into shape by artistry or effort and beaten into shape by tools: hammered – used of metals”.

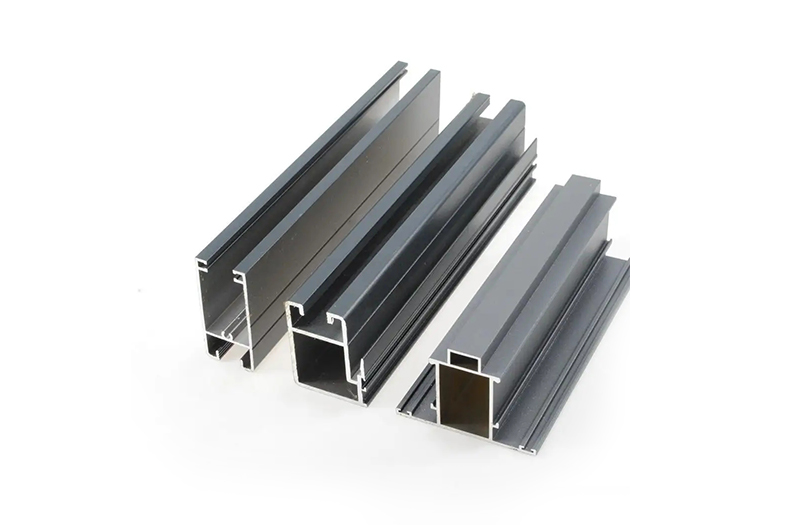

The production of aluminum fences is scalable to huge numbers. An aluminum fence is typically made using a manufacturing process known as extrusion. This procedure entails nothing more than moving blocks of aluminum through a dying system.

cast iron spears. The durable nature of cast iron ensures that these weapons can withstand the rigors of combat and last for many years. This makes them a valuable investment for warriors and collectors alike.

The window profile, or window frame, can be made mainly from three different materials: plastic, i.e. PVC, wood and aluminium. Plastic profiles are the most common and the most economical. Laminated timber frames are valued for their naturalness and rigidity, which is particularly important for larger patio windows. However, they are more expensive, heavier and require regular maintenance. Aluminium profiles, on the other hand, although they have the highest cost, are the most rigid, durable and maintenance-free. This is why their share of the market is steadily increasing, although due primarily to their high price, they still do not exceed a few percent.

However, the characteristic that makes Profilati Alluminio stand out among other aluminum window profile manufacturers lies in the technology used by the company that allows the creation of very small and thin, customized extrusions which are difficult to find on the market.

sliding wheel channel. The sensitivity, speed, and feedback of the channel must be calibrated to provide a responsive and satisfying experience. This involves intricate algorithms and hardware optimization, ensuring that each movement translates into precise digital action without lag or error.

sliding wheel channel. The sensitivity, speed, and feedback of the channel must be calibrated to provide a responsive and satisfying experience. This involves intricate algorithms and hardware optimization, ensuring that each movement translates into precise digital action without lag or error.

The Advantages of Aluminium Profiles